Plexiglass (Acrylic sheet) is a well-known, durable, and good alternative to conventional glass. It is an especially preferred material by DIY guys due to its lightweight, flexibility, and durability. But making it able to fit your project may need you to cut it into different pieces. In this guide, you’ll learn how to cut plexiglass easily without scratching.

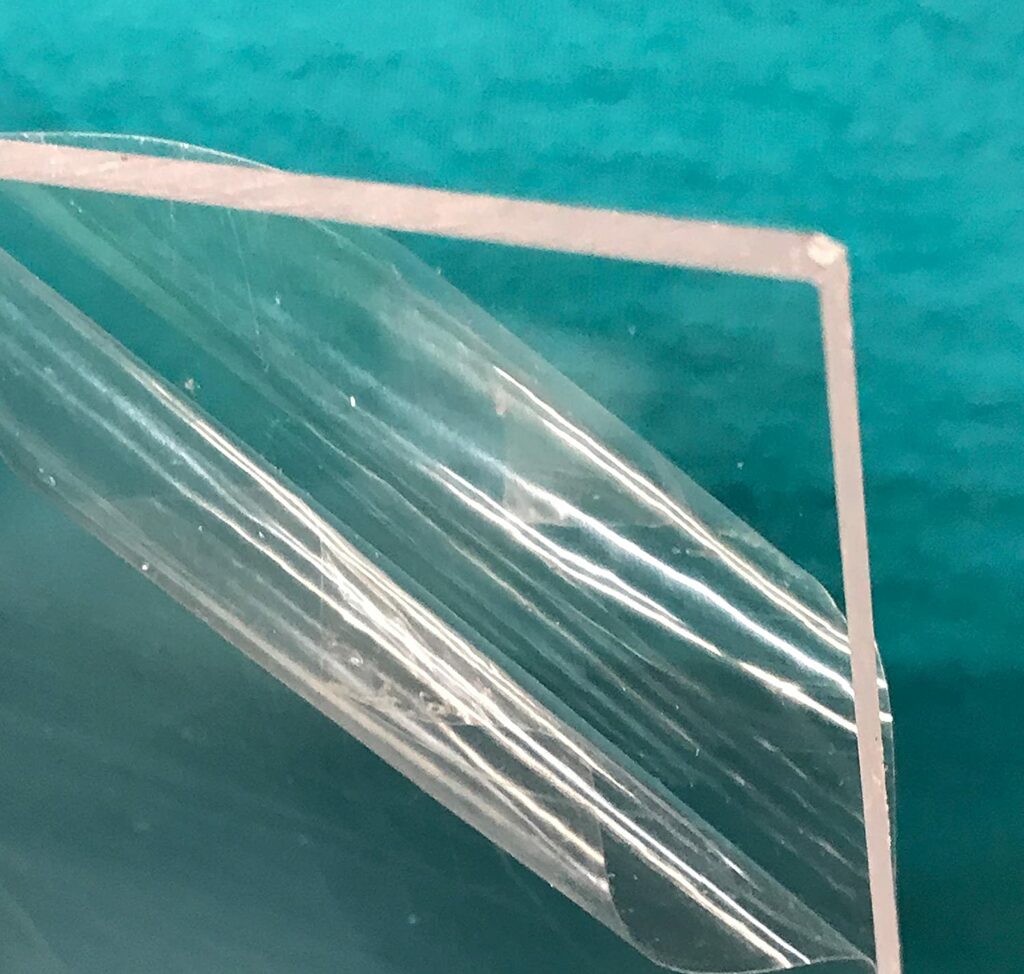

Plexiglass is used in picture frames, tabletops, and windows, etc. It is versatile, shatterproof, and a good substitute for conventional glass. But it scratches easily. Due to this problem, a thin layer of the protective film is covered on its surface to save it from scratch.

Homeowners and DIYers who don’t know how to cut plexiglass may scare at first due to its scratching problem. But we are here to help.

Best practices for cutting plexiglass

You need to follow these common tips while cutting plexiglass. Then you can use any tool to cut the material, and if done correctly, you’ll cut it without chipping.

- Leave the protective film on its surface while cutting, as long as possible.

- You may need to smoothen the edges. Because cutting may produce very rough edges.

- Score deeply to prevent it from breaking on unexpected position.

- Use the right blade if cutting plexiglass with a power saw (e.g. miter saw). Check its teeth, they should be of equal hight and shape, well aligned, sharp, evenly spaced with no rake. Normally, a metal-cutting blade, with carbide tips will work.

- Keep the blade cool. OR, you may end up cracking or chipping your plexiglass. You can use water to cool it down, or pause the work for a few minutes.

You may also like these

- How to cut Porcelain tiles

- Best miter saw for homeowners and best budget jigsaw power tools

Use utility knife, box cutter or glass cutter to cut a thin sheet of plexiglass

From a thin sheet of plexiglass, we mean, a material having up to 3/16 inches thick OR up to 1/4 inches thick. For these thin sheets, use the scoring method. Although you can also use Sawing method, it’ll be handy and faster.

The process of cutting plexiglass is as under:

- Laydown your sheet of plexiglass on a table or any flat surface.

- Measure and mark the area you need to cut with a permanent marker and a yardstick.

- Hold the yardstick to the line, and run the utility knife or glass cutter along the yardstick to score the sheet.

- Repeat the step 3 about 10 to 15 times to deeper the score in the plexiglass.

- Flip over the plexiglass and score on its opposite side as well.

- Now hold the scribed line to the edge of your working table. You may need to clamp it as well.

- Apply downward pressure on the scribed portion of plexiglass, that extends beyond the work surface, to snap it off.

How to cut thick plexiglass sheet with a saw (Jigsaw, Circular Saw, Table Saw, and Saber Saw)

For thicker sheets of plexiglass, you should use the sawing method. i.e. You can use any saw to cut it, just like you’ll be cutting any other material. The power saw could be a table saw, saber saw, or circular saw. You can also use a jigsaw if you are cutting a special shape in plexiglass.

The process of cutting an acrylic sheet with any type of saw is almost the same. You may need to clamp the material as well. But you’ll need a special blade for cutting a plexiglass sheet.

There are special blades for cutting acrylic sheets. It helps in cutting it uniformly without chipping. Most of the time, your metal cutting blades will work too. But any blade you use, check for its teeth uniformity first.

While cutting plexiglass using any type of saw, you should always try to cut slowly, as it may heat up the blade, which results in cracking and chipping the sheet. You should water-cool it, or pause for a few minutes if the blade heats up.

How to Polish and Buff Plexiglass Cut Edges

Whichever cutting method you choose, the cut edges will not always look perfect. If your cut edge is visible in your application, be sure to sand and buff it out before moving on.

For polishing and buff cut plexiglass edges, follow the below steps

- To start, use 120- or 180-grit waterproof sandpaper in combination with a wood or rubber sanding block.

- When sanding, start with coarse grits and use increasingly finer grits as the plexiglass becomes smoother. Finish by sanding with 600-grit sandpaper.

- Buff the edge of plexiglass with a buffing pad after you are satisfied with its appearance. Apply a polishing compound formulated for plastic to bring it to perfection.

Pro Tips to Avoid Cracking or Breaking Plexiglass as You Cut

Even though plexiglass is durable, it can still be broken. Use these tips to help prevent permanent damage from happening when cutting your plexiglass.

- Keep the plastic film on. When measure, mark and cut your plexiglass sheets, keep the plastic film on to prevent scratches from your tools and work surface.

- Keep the blade cool. As mentioned earlier, a power saw’s overheated blade can leave plexiglass rough and uneven. To prevent this, let the saw cool down after it starts to overheat. Up to some extent the plastic film will act like a lubicant, but you can also cool it down with soapy water while cutting.

- Score deeply. To ensure a clean break on plexiglas, score deeply and make sure the lines are straight before trying to crack it at the desired spot.

- Use a sharp blade. To make a good cut, it is necessary to use a sharp blade. A dull blade will fight the material and cause cracks or breaks.

Cutting a plexiglass video

Conclusion

Every material has quirks that you can master through practice. DIYers who have experience with woodworking learn how to cut plexiglass in no time.

Working with acrylic isn’t always difficult and it can be used in many future DIY projects. Practicing plexiglass cutting will make you able to another universe of DIYers projects.